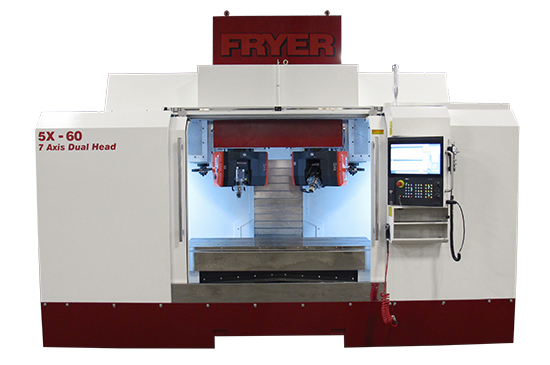

Specialized Machines with Dual Milling Spindles

Fryer manufactures a wide range of milling machines and machining centers in various sizes and travels. All of these machines can be equipped with dual, triple and even quad spindles. 2 axis gimbal type spindles, high speed spindles and 40 taper spindles are all available. Spindles are available in multiple sizes and speeds.

Twin Spindle Milling Machines & Machining Centers

- Adjustable distance between spindles

- 2, 3 or 4 spindle configurations

- Rigid cast iron support

- Automatic tool changers

- Multiple sizes and max RPM choices

Overview

Increase productivity by machining two parts at the same time. Use standard tooling. Equipped with automatic tool changers. Designed from the ground up for multiple spindles. Different spindle tapers available. Different HP and torque options.

Features

- 2, 3, 4 spindle configurations

- Multiple configurations

- High quality components

- Built in the USA

Productivity

- Increase productivity by 100%

- Cut two parts at the same time

- Robot compatible

- Siemens or Fanuc CNC

CNC Control

Overview

The Fryer / Siemens 828-HS control is designed for ease of use in low volume toolroom and job shop facilities. Simple menu programming and fast set-up keys allow you make one-off parts in half the time of a manual machine. Multi mode operation allows you to use the machine manually, semi-automatic and full CNC mode. Canned cycles and graphic verify make set-up faster and easier.

FRYER-SIEMENS 828-HS CNC

- Manual or CNC

- Do-one mode

- Teach mode

- Conversational mode

TECHNOLOGY

- Ultra reliable Siemens High Speed all digital control system

- Regenerative drives save 40% electrical use

- Digital drives provide better accuracy and surface finish

- Absolute encoders never require you to ‘home’ machine

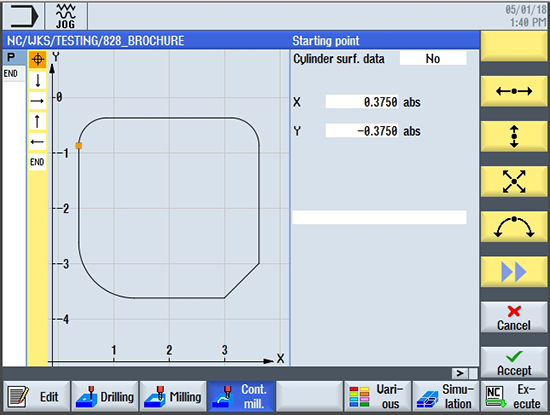

Geometry Creator

Enter part dimensions using the Simple Geometry Creator. The dimensions are drawn on the screen while you enter them and missing information is automatically calculated.

Enter part dimensions using the Simple Geometry Creator. The dimensions are drawn on the screen while you enter them and missing information is automatically calculated.

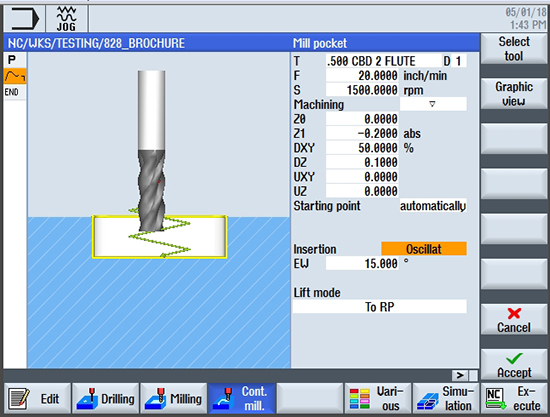

Pocketing Cycles

Choose from a wide variety of pocket shapes. Then answer basic questions about the depth of cut, tool type and finish stock allowance.

Choose from a wide variety of pocket shapes. Then answer basic questions about the depth of cut, tool type and finish stock allowance.

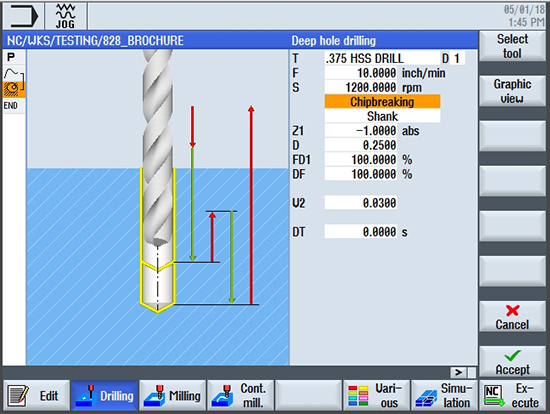

Drilling Cycles

Choose from a wide variety of drill cycles including drill, deep hole drill, peck drill, bore, rigid tap, rigid peck tap and more.

Choose from a wide variety of drill cycles including drill, deep hole drill, peck drill, bore, rigid tap, rigid peck tap and more.

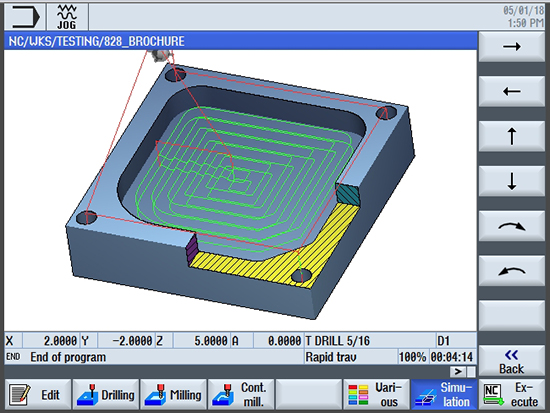

3D Graphic Simulation

The 828-HS uses sophisticated solid model graphic verification to accurately show what your part will look like BEFORE you cut it. Also choose from wireframe or multiview screen.

The 828-HS uses sophisticated solid model graphic verification to accurately show what your part will look like BEFORE you cut it. Also choose from wireframe or multiview screen.