Extra Large Capacity Small Batch Turning

ET-50

ET - XL Series

Easy Turn - Extra Large Capacity Turning

- Easy-to-use Operator Interface

- Fast Set-Up Buttons

- Heavy Duty Construction

- Perfect for Extra Large Part Machining

ET-5050" Swing |

ET-6565" Swing |

ET-8080" Swing |

||||

Center Distances60", 80", 120", 160", 200", 240", 280", 340" |

Spindle Bore Sizes6.1", 9", 10", 12", 16", 20" |

|||||

REQUEST INFO |

||||||

Overview

Fryer Machine's ET-XL Series Lathes provide the ultimate in performance for your large part machining needs. These wide bed (30") heavy duty engine lathes provide incredible capacity to handle the toughest jobs you have. Designed as the heaviest machines in its class, these machines feature centers distances up to 340" and spindle bores up to 20". Innovative features like live tooling, C axis, Y axis, automatic chucks and auto steady rests allow you to customize the machine to best suit your application. The standard Fryer / Siemens 828-HS control features automated set-up and both easy conversational and industry-standard G Code programming. Also featured are thread repair, milling cycles, dual handwheels and incredible reliability.

Features

- 30" wide bed with center mounted ballscrew

- Standard 6" spindle bore

- Three speed autoshift geared headstock

- Full manual mode

- Shop floor programming system

- One button fast setup - simplifies setup process

Quality

- Heavy duty 50 HP high torque spindle

- Hydraulic tailstock with built-in live center

- Heavy Meehanite SP-100 castings

- C3 grade accuracy double nut ball screws

- Digital servo motors and drives with absolute encoders

- Best in class construction

CNC Control

Overview

The Fryer / Siemens 828-HS control is designed for ease of use in low volume toolroom and job shop facilities. Simple menu programming and fast set-up keys allow you make one-off parts in half the time of a manual machine. Multi mode operation allows you to use the machine manually, semi-automatic and full CNC mode. Canned cycles and graphic verify make set-up faster and easier.

FRYER / SIEMENS 828-HS CNC

- Manual or CNC

- Do-one mode

- Teach mode

- Conversational mode

TECHNOLOGY

- Ultra reliable Siemens High Speed all digital control system

- Regenerative drives save 40% electrical use

- Digital drives provide better accuracy and surface finish

- Absolute encoders never require you to ‘home’ machine

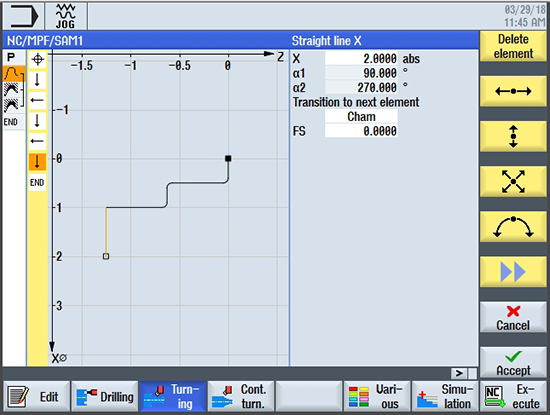

Lathe Contour

Geometry. Enter part dimensions using the Simple Geometry Creator. The dimensions are drawn on the screen while you enter them and missing information is automatically calculated.

Geometry. Enter part dimensions using the Simple Geometry Creator. The dimensions are drawn on the screen while you enter them and missing information is automatically calculated.

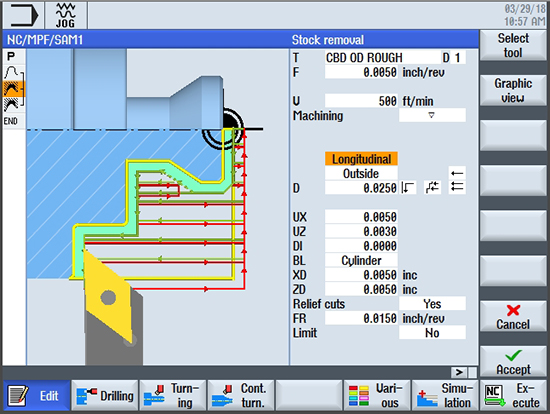

Lathe Rough Cycle

Roughing cycle. Answer basic questions about the depth of cut, tool type and finish stock allowance.

Roughing cycle. Answer basic questions about the depth of cut, tool type and finish stock allowance.

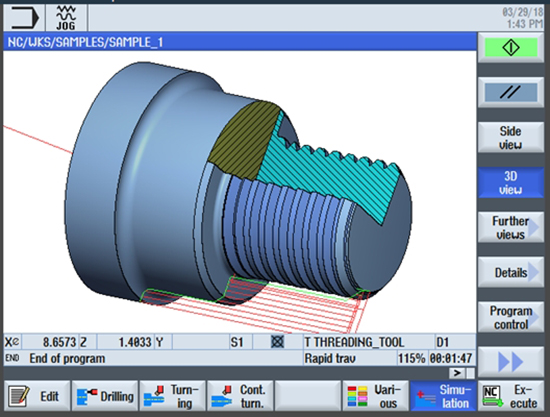

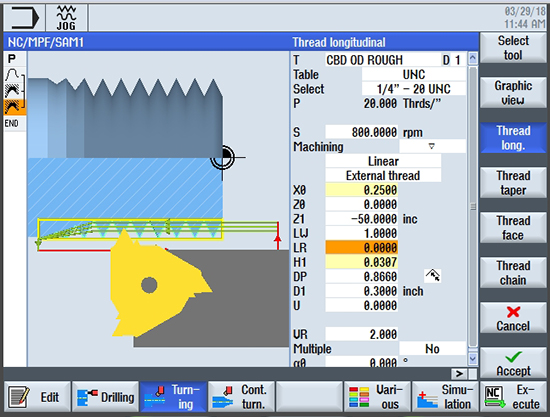

Lathe Thread

Threading cycle. Answer basic questions about the thread size pitch and tool type.

Threading cycle. Answer basic questions about the thread size pitch and tool type.

Lathe Simulate

The 828-HS uses sophisticated solid model graphic verification to accurately show what your part will look like BEFORE you cut it. Also choose from wireframe or multi-view screen.

The 828-HS uses sophisticated solid model graphic verification to accurately show what your part will look like BEFORE you cut it. Also choose from wireframe or multi-view screen.